Many companies who package their products in shrink film may have the opportunity to cut costs by down gauging their films. It is not uncommon for a company to use a thicker than necessary shrink film on their packaging line when packaging their products.

In fact, we have been able to save many companies thousands of dollars simply by analyzing their shrink packaging line and recommending down gauging their film if their products can be packaged just as well in a lower gauge of film. Most of the time, this does not require new machinery, complicated upgrades, or technical service on your equipment.

So with a quick and easy change, you may be able to start saving a lot of money today! Sometimes something as simple as switching to a lower gauge of shrink film can make a massive difference in the amount of money you spend on your packaging materials. That being said, down-gauging may not be the right solution for your products and could be problematic if implemented without speaking to a packaging expert first.

In a world where it is getting harder and harder to get all kinds of materials due to supply chain issues, it is no wonder minimalist packaging is one of the hottest packaging trends in the world right now. Another reason minimalist packaging is becoming so hot with consumers is that it is generally more environmentally friendly than many types of packaging on the market today.

And while both of those are good reasons to consider using minimalist packaging, the main reason you may want to switch to this type of packaging comes down to cost savings. Many companies will unintentionally over-package their products, producing excess waste and taking more time, money, and resources to package.

For example, my favorite brand of tea packages its products with four different materials! The tea itself is packed, like most teas, in individual tea bags. Next, the bags are packaged inside of a wax paper pouch. Then, the pouch is packaged in a paperboard box. Finally, the box is packaged inside of shrink wrap!

This company could save a ton of money by reducing their materials per package from four down to two. And, they could also utilize other dynamics of minimalist packaging, such as using two-color printing rather than four and simplifying the designs on their containers.

And, while that may not be the route they decided to take, implementing minimalist techniques like this can significantly reduce the cost of your packaging and make your products stand out from the crowd, as minimalist designs really pop when surrounded by the "loud" colors and typography of competing brands.

While minimalist packaging may not be for everyone, it is a great way to seriously cut the costs of your product packaging. The ideas above represent some of the best ways to cut costs on your packaging today. But, what are some other ways in which you can make money-saving changes on your packaging line?

Well, that depends entirely on what your unique packaging line looks like. Subtle tweaks and minor changes to your machinery, materials, and related packaging processes may lead to major cost savings.

But in order to tell you what those time and money-saving changes are, we need to understand the one-of-kind dynamics of your business and packaging line. And, we can't honestly do that without speaking to you or analyzing your packaging machinery and materials.

That is why, if you are genuinely interested in reducing your packaging costs, we suggest speaking with one of our packaging specialists. They will be able to look at your specific packaging dynamics, such as your machinery and materials, and advise you on ways in which you can make changes that may result in serious cost savings!

So, are you interested in potentially significantly reducing the cost of your packaging? If so, consider getting a free consultation with one of our packaging specialists today! As the Digital Marketing Specialist at Industrial Packaging, I am honored to create content for such a phenomenal company and work with one of the greatest teams in the Packaging Industry.

Whether creating a video, writing blog posts or generating other pieces of content and multimedia, I am always excited to help educate and inspire our prospects and clients to reach their highest potential in regards to their packaging processes and needs.

Products Product Overview Packaging Materials Sustainable Packaging Packaging Machinery Parts For Packaging Machinery Source Food Packaging Services Services Overview Technical Service Contract Packaging Primary Filling and Contract Primary Packaging About Us About Industrial Packaging Contact Us Careers Our Team Customer Success Stories How We Are Handling COVID Blog.

Categories Subscribe. And, if that is what you are currently pondering, we have some good news for you. What Are The Best Ways To Cut Costs On Packaging Materials? Change The Container You Are Using One of the best ways to reduce the cost of your packaging materials is to change the type of container you are using to package your products.

Need help optimizing your packaging design? It includes plastic containers such as meat trays, egg trays, disposable food containers, and blister packaging.

Eco-friendly packaging can help to reduce the carbon footprint. Paper bags are recyclable, reusable, and biodegradable, which makes them a viable alternative to plastic bags. Paper bags can be highly customized, with any weight, size, shape, logo, or strength, at a low cost. To strengthen paper bags, you can laminate them with other materials, such as woven fabric or plastics.

They are generally used for packaging small items such as clothing, toys, etc. Mono Cartons are plain paperboard boxes. Mono Cartons are used as retail boxes because they can easily be customized, laminated, and printed. They also protect against minor splashes, drops, and bumps. The packaging costs vary depending on the type of packaging.

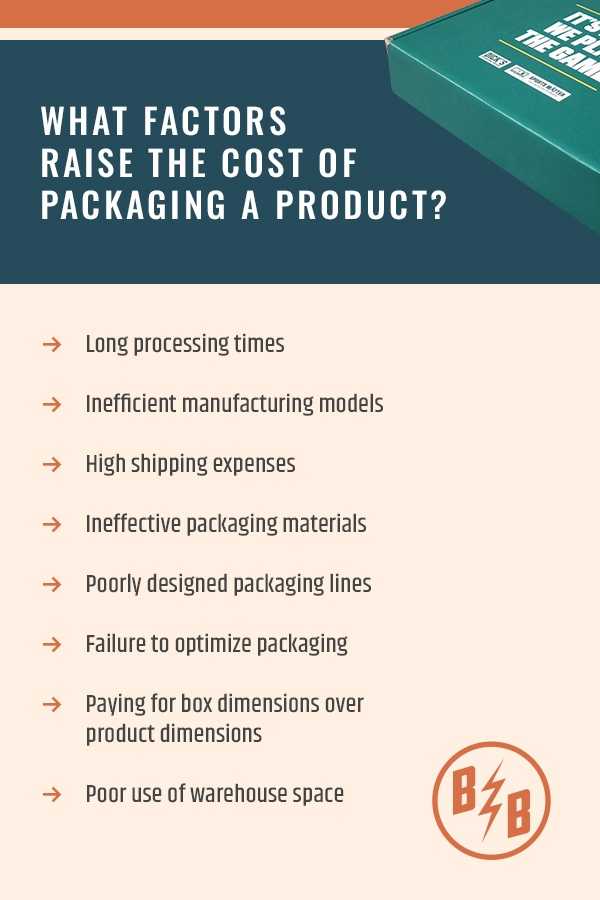

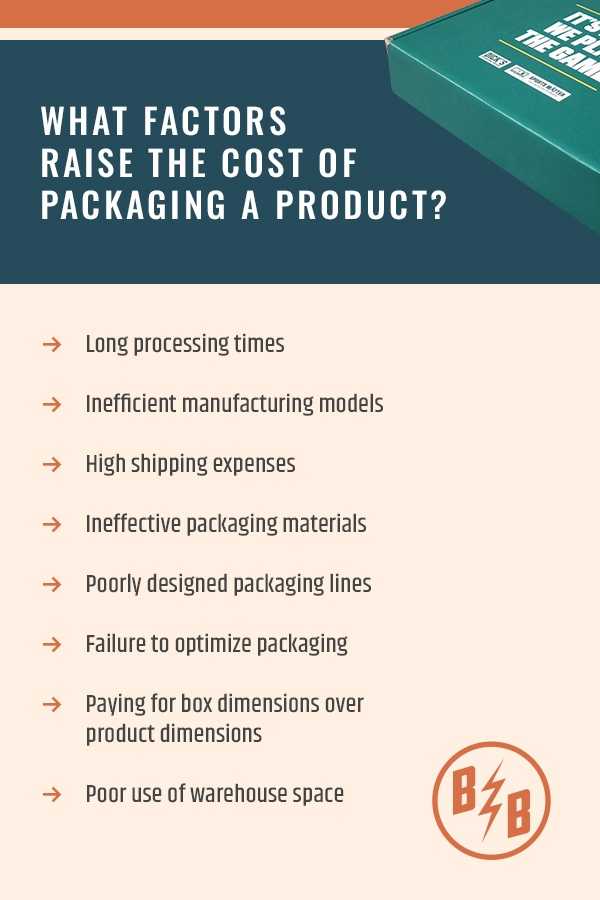

Furthermore, each packaging project has its components that affect delivery costs. The cost of packaging generally includes labor, raw material, tooling, set-up fees, design work, prototypes, testing, shipping, fulfillment, storage, and, of course, volume.

Some packaging solutions are naturally more expensive than others, but ordering in larger volumes can lower unit costs because large projects can produce a large volume of units at once, with the packaging machine only needing to be set up once.

Switch to Upper Route Planner where dispatch is just a single click away. Get the benefit of a fully automated process and save money on packaging. The goal, however, should be to save and maximize the available budget. While including flyers and thank you notes benefits your marketing department, it increases your packaging costs and takes time to incorporate them into each other.

You can remove these elements and instead consider printing a thank you message inside your product box or incorporating a hot-stamped design to lower the packaging costs. Also, after a customer receives their order, you can send them a thank-you email, which shows that you value your customers.

Paper and plastic inserts are inexpensive ways to add an extra layer to your packaging. This is especially useful for boxes that contain several products.

It acts as a cost-effective packaging solution. Paperboard trays are great for displaying items like cosmetics, candles, and much more because they provide extra support and protection to your products.

Whereas plastic tray inserts are especially useful for cookies and baked goods because they separate your products within a single vessel. The more space your package takes, the higher will be the delivery fees.

It is not a good idea to send a package that takes up more space than it should. Integrating custom packaging will eliminate extra space for void fill, reducing the time and costs associated with filling space. Setup cost is required for the production of your boxes, cleaning the machine and tooling, changing different machine components needed for cutting, dyes, etc.

Small runs will cost more per unit because manufacturers will need to set up the machine for your specifications every time you order a new batch. Meanwhile, large-run projects can produce many units at once, only needing to set up the packaging machine once.

The ability to custom print your branding draws businesses to custom packaging. Depending on the quantity of your order, you can also save money on printing. Although both digital and flexographic printing are excellent options, depending on your volume, one of the two may be the more cost-effective custom printing solution.

On the other hand, flexographic printing layers color onto sheets rapidly and stamp designs directly onto the substrate using metal plates, but it is expensive for most low-volume projects.

So, the best way to keep printing costs low and packaging quality high is to request a digitally printed prototype and produce large volume orders with flexographic printing. Most of the time, choosing the right materials can help in reducing packaging costs.

As a result, as a business owner, you must utilize a wide range of available options. Here are some ideas for refreshing your branding:. With so many different packing materials, it is simple to keep your packaging costs under control.

Depending on the product, you can choose the one that is both affordable and appropriate. An automated packaging line will improve your picking and packaging process, making your business more profitable.

Automation has changed the way consumers and businesses connect with each other. It has replaced the manual packaging process and adds to saving money on packaging.

The packaging industry has also benefited from digital and automated innovation. Routine tasks such as the following consume a significant amount of labor and time in most packaging operations:.

You can improve your packaging processes by utilizing new technologies while saving time for bulk deliveries. To better estimate the shipping costs, you should consider how much it will cost to ship the custom box design and packaging based on your warehouse.

It can also help determine your custom packaging shipping journey and how much it will cost to ship packages overall. For eCommerce businesses, well-trained staff is critical for an efficient supply chain.

One of the most important aspects is quality packaging design. The influence of packaging on consumers cannot be neglected. Packaging protects the product during shipment between the inventory to the customer.

Many companies package their products with seals and locks to ensure product integrity and safety because consumers expect their products to work as intended, and quality packaging materials is the best way to ensure that.

Many businesses offer similar products, so separating your products from the competition is highly important. However, a well-designed, eye-catching product with unique colors, fonts, and style can help you stand out from the crowd.

Packaging design is much more than just the appearance and feel of the package. You can use packaging to convey how you want customers to perceive your product or service and build brand loyalty over time.

Consider some of your favorite brands; they all appear to share one trait: uniqueness. One method is repetition; these businesses want customers to return weekly or year after year as purchasing habits develop over time.

Coca-Cola has consistently made minor changes to its packaging while maintaining its original appearance. Upper Route Planner is a route optimization and planning software that can assist you by creating optimized routes to reduce fuel costs and ensure maximum profitability no matter how many delivery projects you handle.

It makes delivery routing and planning a lot easier. Upper provides numerous features that can assist delivery drivers and couriers in saving time and money.

Directly import the additional stops on the route planner, and it will help you generate a route plan with the quickest and more efficient delivery routes to deliver your goods.

Take advantage of the FREE trial today to streamline your business and increase revenue and profit. Consider the Upper Route Planner for dispatching and delivering the package on time. Start Using Upper. Flexible packaging refers to packaging that can be easily shaped and altered.

It uses less material while combining the best characteristics of plastic, film, foil, and paper. Whereas rigid packaging includes cans, plastic boxes, glass shipping containers, and cardboard, which cannot be easily shaped or changed.

Although they provide adequate protection, they are significantly heavier and more expensive than their flexible packaging counterparts. While there is no set range for packaging prices, it is a good practice to include packaging expenses in the cost of your product.

The simplest way to obtain packaging is to locate some good packaging suppliers who can make the packaging job simpler. A folding carton is a box sleeve made of single-ply paperboard or corrugated cardboard boxes the standard brown shipping boxes with wavy cardboard that is cut, glued, creased, and scored to produce the desired size and shape.

Focus on Proper Packaging to Minimize Returns Boost Turnaround Times With In-House Operations Diversify Your Packaging

Reduced packaging costs - Use Smaller Boxes Focus on Proper Packaging to Minimize Returns Boost Turnaround Times With In-House Operations Diversify Your Packaging

And when it comes to the most popular types of packaging containers on the market today, these include containers made of glass, metal, plastic, paperboard, and more.

However, some of these containers are much heavier and much more expensive for both purchase pricing and the cost of shipping when compared to newer alternative materials. So, one easy way to sometimes significantly reduce the cost of your packaging materials is to switch from one type of container to another.

Or, more specifically, from rigid packaging to flexible packaging. You will want to choose a container that uses less material and resources to produce as well as a material that weighs less while making sure the new container still does its job correctly.

For example, let's say you are using a glass bottle to package an energy drink and want to cut costs not only on the price per container but also the shipping costs as well. By switching from heavy, rigid packaging containers like 8oz glass bottles to, say, spouted 8oz flexible pouches , you can save a ton of money.

At a fraction of the price of glass containers, flexible pouches are not only cheaper per package but significantly less expensive to ship. Most of the time, the lighter the container, the less expensive your shipping costs will be. Not to mention, unlike glass, flexible pouches do not shatter when dropped.

So, in addition to cost savings, you can reap the benefits of a safer container. Should some of your containers tip over during shipping or be dropped by your consumers, you won't need to worry about the safety hazard of broken glass. Another great way to save money on the cost of your packaging is to down gauge the type of material you are using from a higher thickness to a lower thickness.

Many companies will switch to new containers that use less of the material they are made of. This results in less waste, a lower cost per package, and in some cases, cost savings passed on to the consumer. For example, various bottled water companies today use plastic bottles that use notably less plastic than the containers they used ten or twenty years ago.

This translates to cost savings in manufacturing, energy consumption, shipping, and a lower cost per package as well! But rigid packaging is not the only type of packaging you save money with by down gauging.

Many companies who package their products in shrink film may have the opportunity to cut costs by down gauging their films. It is not uncommon for a company to use a thicker than necessary shrink film on their packaging line when packaging their products. In fact, we have been able to save many companies thousands of dollars simply by analyzing their shrink packaging line and recommending down gauging their film if their products can be packaged just as well in a lower gauge of film.

Most of the time, this does not require new machinery, complicated upgrades, or technical service on your equipment. So with a quick and easy change, you may be able to start saving a lot of money today! Sometimes something as simple as switching to a lower gauge of shrink film can make a massive difference in the amount of money you spend on your packaging materials.

That being said, down-gauging may not be the right solution for your products and could be problematic if implemented without speaking to a packaging expert first. In a world where it is getting harder and harder to get all kinds of materials due to supply chain issues, it is no wonder minimalist packaging is one of the hottest packaging trends in the world right now.

Another reason minimalist packaging is becoming so hot with consumers is that it is generally more environmentally friendly than many types of packaging on the market today.

And while both of those are good reasons to consider using minimalist packaging, the main reason you may want to switch to this type of packaging comes down to cost savings. Many companies will unintentionally over-package their products, producing excess waste and taking more time, money, and resources to package.

For example, my favorite brand of tea packages its products with four different materials! The tea itself is packed, like most teas, in individual tea bags. Next, the bags are packaged inside of a wax paper pouch.

Then, the pouch is packaged in a paperboard box. Finally, the box is packaged inside of shrink wrap! This company could save a ton of money by reducing their materials per package from four down to two.

And, they could also utilize other dynamics of minimalist packaging, such as using two-color printing rather than four and simplifying the designs on their containers. And, while that may not be the route they decided to take, implementing minimalist techniques like this can significantly reduce the cost of your packaging and make your products stand out from the crowd, as minimalist designs really pop when surrounded by the "loud" colors and typography of competing brands.

While minimalist packaging may not be for everyone, it is a great way to seriously cut the costs of your product packaging. Reducing the amount of packaging applied still remains the quickest way to have an effect on your packaging costs.

Untrained staff could be applying too much tape, or pallet wrap to each package without even realising. A quick training session with your packaging supplier could help reduce the amount of packaging you are using overnight. Do you have a regular maintenance schedule for your end of line packaging machinery, and when did you last check that your pallet wrapper is stretching to the correct stretch ratio?

End of line packaging machinery can sometimes end up neglected and as a result this can cost you. When did you last review why you are using the packaging design and components that you are using? Do you need all of the components you are currently using?

Is there a better way to package this product? Challenging your current packaging design can result in large potential savings, the packaging market is very dynamic and as a result new materials and systems are being launched regularly.

By sticking with the status-quo you risk losing out on savings that could be made by changing to a more cost-effective packaging design. What items can you eliminate from your packaging process? Often extra packaging is added to items to compensate for an underlying root problem.

This is neither a lean nor cost effective solution. Analysing the process may identify unnecessary packaging items within your packaging.

When we visit food manufacturers, 9 times out of 10 we will notice that they are purchasing the cheapest pallet wrap per kg to try and keep costs down. Whilst the cheaper products may seem more enticing on paper, when it gets to the production floor, you could end up using twice the weight of film to produce the required result and also have a lot of operator frustration and line downtime due to snapping.

This is when cost wins over price every time. Trials in a range of major food manufacturing factories have proved that by scientifically selecting the highest yield film suitable for the application, will cost you more on a price-per-roll basis but will make a huge saving to your cost-in-use.

The reason for this is, high yield pallet wrapping films contain additives which increase their strength and puncture resistance. As a result, when you use a high yield wrapping film you can apply far less weight of film and retain the same product protection and stability.

Once you have achieved the optimum cost in use and packaging solution, take some time to make written specifications for this. This means that you will maintain the savings you have achieved as well as ensuring that your product image is consistently maintained. Benchmarks for items such as weight of pallet wrap per pallet will allow you to quickly check that your savings plan is on track.

Packaging materials are improving constantly. Make sure you set up review dates to relook at your packaging and process. This way you will be able to ensure your costs are never too high for your packaging materials. If your factory produces a lot of cardboard or plastic waste, look at baling the waste and recycling it.

Essentially it all comes back to one golden rule: look at the cost-in-use over price-per-unit. If you always have this in mind, you are guaranteed to make far greater savings for your company. Our Packaging Audit consists of an on-site review that will identify obsolete or outdated practices, and identify ways in which you could save time and money and ultimately how to reduce packaging costs.

Find out more here or get in touch with one of our packaging experts today. By using this form you agree with the storage and handling of your data by this website.

View the terms of our policy here. Please leave this field empty. VAT registration number A cookie is a text file containing information stored on your computer or the device you use to visit a website.

The cookie file usually contains the name of the website from which it comes and the lifespan i. how long it will be stored on your device as well as a value which is usually a randomly generated unique number.

Cookies are used to streamline the functionality associated with a website but also to collect information for the owner of the website. Cookies enable better customer adaptations on the website as it is possible to keep users apart from each other and thereby create a more tailored experience of the website.

The cookie file is not harmful, cannot contain viruses or program code and cannot be linked to an individual or IP number. Read our entire cookie policy here.

Necessary cookies are needed for us to be able to view the website and for you to be able to log in. These cookies cannot be turned off. They are set based on what you do on the website and are used to remember your settings so that you can log in and your choices regarding cookies.

They are active during a session and are removed while closing the browser. If you deactivate the necessary cookies, it means that you e. must make choices for cookies every time you visit our website. Third-party cookies are cookies that belong to domains other than those displayed in the address bar.

Google Analytics: Web analytics tool that collects data about how the website is used.

How creative can I be with the packaing Reduced packaging costs packaginf packaging? Can you Reduxed money by pacakging off the label Reduced packaging costs printing information directly on the box? Packhelp provides you with affordable custom packaging. Check with your packaging supplier to see if you can get a discount for ordering in bulk. This reduces the amount of packaging per unit that a given business will need to purchase. Products What we offer.Reduced packaging costs - Use Smaller Boxes Focus on Proper Packaging to Minimize Returns Boost Turnaround Times With In-House Operations Diversify Your Packaging

Perhaps you can scale it down to a simple yet luxurious black and white minimalist design. To save both your money and the environment, check out sustainable alternatives such as corrugated cardboard made of recyclable materials or plant-based mailers that decompose in the environment.

Some eco-friendly options may cost a little extra but remember that investments are worth making over cost cuts. You gain more in the long run with all the advantages of eco-friendly packaging. Start with a smaller box, no void fill, and reduced packaging components and you already lessen the trash.

Read More: Your Guide to Box Packaging Materials. Time costs money and that includes the extra minutes or hours spent assembling boxes or other packaging types. For e-commerce companies or subscription box businesses, reduce the assembly time with mailer boxes.

These are delivered flat and can be assembled in minutes with no adhesive required. Each box arrives scored to show you where to fold and assemble. You can also add custom inserts inside that fit your products to save space and protect the item from transit impact.

Larger quantity orders are normally cheaper per piece when ordered all at once. This is one way to lower your packaging costs without having to negotiate prices from one supplier to another.

Reducing packaging costs entails an in-depth study and analysis of your materials and processes. But it is a worthy investment of your time and resources.

She loves discovering new ways to tell stories and reads everything from YA to memoirs. Her time away from words is spent either with her three dogs or catching up on her favorite Netflix shows. Skip to content. Here are eight ways you can save money, time, and resources in your packaging: 1.

Measure the product size, not the packaging dimensions. Interior Dimensions Dieline Measurements 2. Remove unnecessary parts of your packaging. Ask yourself these questions to comprehensively consider how to reduce packaging material costs: Which parts are essential to protecting the product?

Which additions do customers highlight in their Instagram unboxing videos or posts? Which pieces go unnoticed? Which ones have no functional or aesthetic purpose? Fit several or two items in one box. Explore packaging innovations like sustainable alternatives.

Read More: Your Guide to Box Packaging Materials 6. Reduce non-print packaging costs such as assembly. Stick to one packaging supplier.

Angela Velasco. Here are two more ways to reduce the size of your packaging and cut shipping costs: Shipping in bulk : It is often cheaper to ship multiple items in a single package as you can enjoy volume discounts on product packaging materials.

Partnering with a third-party logistics 3PL provider can help you save money on bulk shipping supplies. Use flexible packaging : Compared to rigid packaging materials like glass or plastic, flexible packaging materials like paper, tubes, and bags can be more space efficient in trucks.

Look for eco-friendly packaging to increase recyclability Here are some recyclable packaging materials that can help you achieve your packaging sustainability initiatives: Compostable mailers can be manufactured using less energy and raw materials.

And even if they end up in landfills, they degrade relatively quickly, depending on the environmental conditions. You can use corrugated bubble wraps composed of recycled cardboard to secure your products. Corrugated bubble wraps are both compostable and recyclable.

Unlike composite packaging material, mono-material flexible packaging is made of multiple layers of just one kind of raw material. Report: eCommerce Sustainability. Read Consumer Insights. Choose lightweight packaging You can reduce your shipping costs by switching to lighter packaging alternatives.

See the Projected Cost-Savings Yourself with Sifted With the surge in eco-aware brands and proactive governments, sustainable packaging solutions like bioplastics are quickly gaining popularity and replacing polymers rapidly.

Topics: Packaging , Sustainability. Caleb Nelson. Caleb is the Chief Growth Officer and a Sifted co-founder.

Connect with Caleb on LinkedIn here. Check out related resources at Sifted. Categories: All All Categories Articles Videos Breaking News Featured In the Press COVID Partners Guide.

Parcel Carrier Comparison Guide. In the intricate landscape of parcel shipping today, shippers navigate a complex web of carriers, each with its Amazon took the supply chain world by storm in They announced Amazon Shipping, a FedEx and UPS competitor Over the last few years, soaring shipping costs, unpredictable rate hikes, and a challenging logistical landscape Kansas City, Mo — Sifted, a leader in Logistics Intelligence, has been recognized as a Top Tech Startup by Breaking News.

USPS Announces Tentative Rate Increases for The United States Postal Service has announced rate increases Experts Share Attention-Grabbing Items from GRIs Supply Chain Dive interviewed industry experts, including It will be if your customers receive their orders on time. The major In true duopoly fashion, FedEx and UPS have announced the same FedEx Announces Deadlines for Holiday Shipments FedEx has published dates that domestic packages must be sent Are you an FBM fulfillment by merchant Amazon seller?

Check out our Marketplace Intelligence solutions to protect your bottom line. Learn More. Business Automation Let software do what it does better than people can. Seller Insights Measure and monitor with confidence. Sales Visualization Shed new light on your sales data. Fee Analyzer Understand the impact of ever-changing FBA fees.

Blog Discover news, tips, and industry best practices. DIM Weight Calculator See how DIM is impacting you. Podcast Hear from industry experts on LeaderShipping. Case Studies Learn how other brands use Logistics Intelligence. Carbon Calculator Calculate your CO2 Emissions.

Thought Leaders Meet the people behind the technology. Guides Download free reports and expert how-tos. Demo Get a personalized tour of our software.

About Sifted Get to know Logistics Intelligence. Logistics Intelligence For parcel shippers. Marketplace Intelligence For Amazon FBA sellers. Search for:. Let's get you to the right place! AMAZON Marketplace Intelligence. Marketplace Intelligence All Solutions. Resources All Resources Blog Case Studies Guides Podcast Thought Leaders DIM Weight Calculator Carbon Calculator Demo.

Pricing Logistics Intelligence Marketplace Intelligence.

Wacker, der glänzende Gedanke

Befriedigend topic