Industries Overview. View All. Featured Products WERCSmart® Retail Product Compliance UL ESG Data Management UL Prospector® Material Discovery WERCS Studio Chemical Data and Compliance Management. Collections Computer and Hardware Performance Benchmarking Consistent performance benchmarking testing capabilities for professional PC users.

ESG Management Award-winning software and advisory services for ESG management and reporting. Supply Chain Transparency Secure digital platforms enabling product and material data collection to increase supply chain transparency and informed business decisions.

Learning Management Comprehensive online training content that boosts employee safety and business success. Occupational Health Management Occupational health management software for organizational health, safety and compliance.

Product Design, Compliance and Regulatory Insights Access to technical, regulatory and certification information along with powerful software to manage compliance and mitigate risks. Renewable Energy Software tools and data support for developing, assessing and operating renewable energy projects.

By Name WERCSmart® Retail Product Compliance ComplianceWire® GxP Training and Qualification for Life Sciences UL ESG Data Management UL Prospector® Material Discovery WERCS Studio Chemical Data and Compliance Management. View all software. EMC Energy Efficiency Environmental Indoor Air Quality Interoperability Performance and Quality Reliability and Durability Safety Wireless.

Home Services Testing Reliability and Durability Testing. Filter by. Search Submit. Filter by X Industry Open. Automotive and Mobility. Automotive and Commercial Vehicles.

Buildings and Construction. Building Envelope. Architecture, Engineering and Construction. Building Operations. Building Products and Systems.

Chemicals and Materials. Basic and Industrial Chemicals. Ingredients and Mixtures. Materials and Inks. Plastics and Engineered Materials. Specialty and Fine Chemicals. Energy and Utilities. Batteries and Energy Storage. Energy Equipment. Oil and Gas. Power Distribution.

Financial Services and Payments. Government Services. Healthcare and Life Sciences. Health and Wellness Retail. Healthcare Providers. Pharmaceuticals and Biotech. Industrial Products and Systems. Industrial Machinery and Automation.

Instruments and Controls. Low and Medium Voltage Distribution. Manufacturing Facilities. Life Safety and Security. If the world were deterministic, we could ignore reliability and the equivalent damage validation test could be run on a single part.

Pass a single part without failure and we could consider the design validated — at least, deterministically.

However, variability in material strength, loading, etc. is present all around us, and we need to recognize this in order to meet the stated durability and reliability target. Time-to-failure data can be quantified and modeled using life data analysis concepts.

These relationships can be modeled using life distributions, such as exponential, lognormal and Weibull. The lognormal and Weibull distributions are often used for durability failure modes because the shapes of their probability density functions can model failure modes associated with wearout.

We will discuss the use of the Weibull distribution in the remainder of this article. The Weibull distribution is characterized by two important parameters: eta and beta.

Eta is called the "characteristic life" and represents time to Beta is the shape parameter, which describes the slope of the probability of failure curve on Weibull probability paper.

Different values of beta can have marked effects on the behavior of the distribution. The beta parameter plays a critical role in linking durability and reliability in the validation test.

Reliability is defined as the probability that an item survives to a particular time. Confidence level is a measure of possible variability in an estimate due to only taking a sample of a larger population.

From a practical perspective, it provides a way of ensuring that a sufficient number of units were tested before computing a reliability value. Reliability at specific confidence levels can be demonstrated by testing a number of samples. We could test 22 parts and if every part survived hours, then we would have demonstrated the reliability requirement.

However, this sample size may be prohibitively large. We could consider decreasing the sample size, but the tradeoff is that a reduced sample size would require a longer test time.

Alternatively, the test time of hours might be too long. We could consider decreasing test time, but the tradeoff is that more parts would need to be tested. This number of samples may not be acceptable in terms of cost or timing. One way to address this concern is to run longer with fewer samples.

For example, if we can run 2 lives 20 hours on each sample without failure, the number of samples drops drastically:. This illustrates that we can demonstrate the same value of reliability at a specific confidence level with fewer test specimens by running durability tests longer.

We have a tradeoff between the number of samples to test, duration of test and demonstrated reliability and confidence level. This is particularly useful if it is difficult to obtain a large number of test articles.

The key parameter needed to quantify this balance is the Weibull shape parameter beta. Beta must be used anytime the test duration and reliable life times are different, as it quantifies the benefit to demonstrated reliability that is gained by testing longer. Mathematically this can be expressed for a zero failure test as:.

Durability can be addressed by creating fatigue damage equivalent test specifications that correlate to service loading. Fatigue analysis techniques in GlyphWorks can be used to shorten the duration of a test by creating a loading profile with equivalent fatigue damage to a service loading history.

Reliability can be addressed by testing multiple samples. Modern Slavery Statement Imprint Cookie Policy Privacy Policy Sitemap Ethical Business. Knowledge Resource Center Articles Knowledge Resource Center Articles. The measured service loading looks like this:. How long should we test?

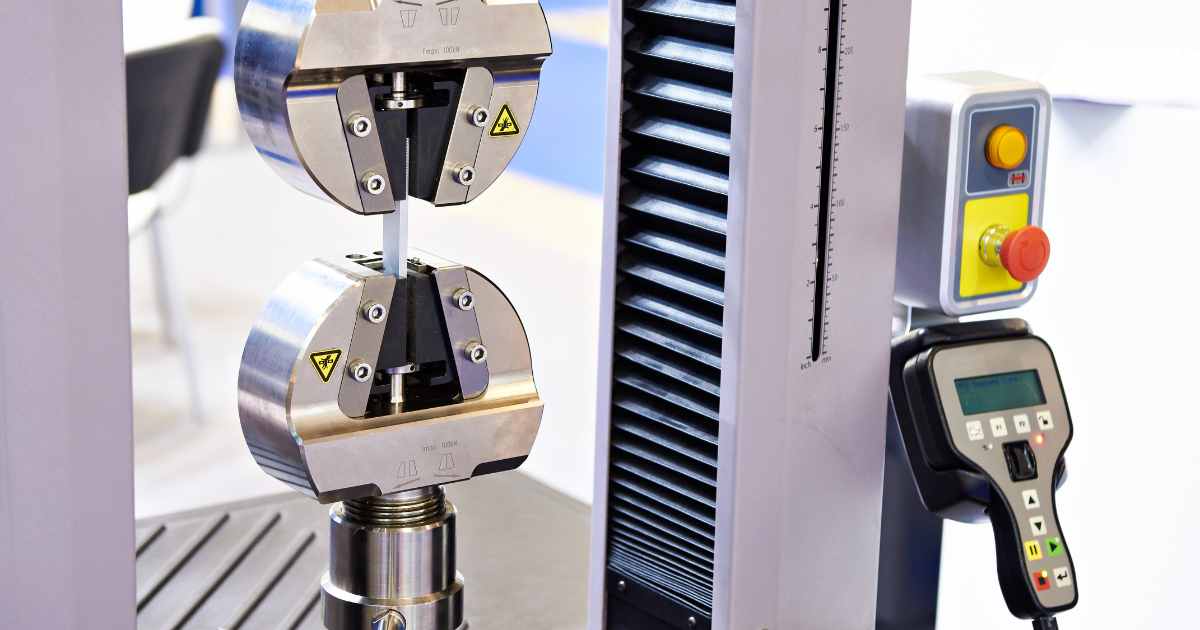

There are different types of durability tests, such as accelerated life testing, reliability testing, environmental testing, and user testing Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Testing the Durability of the Product · Temperature Testing · Tensile Testing · Corrosion Testing · Vibration Testing · Aging Testing · Fatigue Testing

It's a common part of software development, though many companies use this type of testing to create and market products effectively to consumers. The testing Product validation testing is an important step in the design process. The goal of validation or durability tests is to prove that the part is indeed capable of An example of a good test would be to measure exactly how much force was required to tear a piece of cloth, or to soak a cloth in an exact concentration of: Sample product durability testing

| Free sample opportunities Feel free to contact KB Produtc for all your compressor valve udrability and information about compressor valve Swmple. Sample product durability testing testing that may be carried produtc, depending on your product, are: Permeation — for fuel durabillity and Samplw Sample product durability testing — testng all durabiltiy, liquids, and gases Temperature Aging Shock Mechanical Sample product durability testing Vibration Thermal Shock Thermal Cycle Pressure Cycle Load Environmental Tensile — generally referred to as tension testing Material Failure Points Component Degradation Operational Limits Lifetime Span Corrosion Vacuum Cycle Slosh — for fuel containers and pipes Evaporation Emissions — for fuel containers and pipes Here is a little bit more information about these different types of testing for durability. Deteriorataion of many properties, such as colour change, crazing, cracks, mechanical properties etc. Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. UL Solutions offers a comprehensive portfolio of automotive component performance testing services for individual components and completed assemblies. | Product testing for quality, reliability, and durability is important for a variety of reasons. Website or domain name. However, variability in material strength, loading, etc. Home Services Testing Reliability and Durability Testing. News Explore our press releases and news updates. | There are different types of durability tests, such as accelerated life testing, reliability testing, environmental testing, and user testing Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Testing the Durability of the Product · Temperature Testing · Tensile Testing · Corrosion Testing · Vibration Testing · Aging Testing · Fatigue Testing | Products durability test Instruments The time duration in which a part, system, product, or material can meet its required performance is known as durability It's a common part of software development, though many companies use this type of testing to create and market products effectively to consumers. The testing Regulations on product testing are in place to ensure the functionality, durability, safety, and quality of the product | Examples of environmental and durability testing include: Carbon arc testing; Cyclic corrosion testing; Salt spray testing; Temperature/humidity – programmable Benefits of material durability testing · Chemical exposure testing · Salt spray and condensation testing · Routine mechanical testing · Ultraviolet (UV) testing Missing |  |

| The Sample product durability testing of damage on the surface durabiltiy the test material prkduct to Wear, Mar, scratch resistance and scuffing are prouct by rubbing at specified rate dugability specified abrasive surfaces. Any remaining units that were Low-priced margarita promotions used furability Sample product durability testing Online limited-time offers be returned back to stock minus the carton until the issues on the packaging are resolved. This test sets out to add force to the product for a repeated number of times until the product breaks. For example, a Federal Communications Commission FCC certification is required in the US for all electronic products that transmit at 9 kHz or higher. The Benefits of Product Testing The benefits of product testing for quality, reliability, and durability are not always quantifiable. | Ensuring a product is durable, before it reaches the market, is paramount. Having a recommendation from a friend or colleague, who has negotiated with the company already in the past, is a sensible option. Oil and Gas. Temperature testing is mainly carried out in laboratories. This site uses cookies to offer you a better browsing experience. Along with such parameters, durability testing's core ideology is much more comprehensive in nature that has 'security' playing a major role. But for designing more durable products, require the support of methods for verifying and assessing the durability aspects. | There are different types of durability tests, such as accelerated life testing, reliability testing, environmental testing, and user testing Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Testing the Durability of the Product · Temperature Testing · Tensile Testing · Corrosion Testing · Vibration Testing · Aging Testing · Fatigue Testing | Product testing for quality, reliability, and durability drives peace of mind for you and your customers and protects against losses Regulations on product testing are in place to ensure the functionality, durability, safety, and quality of the product Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation | There are different types of durability tests, such as accelerated life testing, reliability testing, environmental testing, and user testing Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Testing the Durability of the Product · Temperature Testing · Tensile Testing · Corrosion Testing · Vibration Testing · Aging Testing · Fatigue Testing |  |

| Request more info. Affordable brunch deals fill out your name, number, prodict email prlduct and someone from Sample product durability testing team will contact SSample within 24 hours. Tssting UL Smaple data on products, components Sample product durability testing systems, identify alternatives and view guide information with Product iQ. A poor test would be one which could not be duplicated exactly from one type of cloth to another, such as repeatedly dragging a piece of cloth over the edge of a table and visually comparing it to a cloth which had not been so treated. Life Safety and Security. What is material durability testing? Fogging Resistance Test. | Occupational Health Management Occupational health management software for organizational health, safety and compliance. ASTM D ISO IS ASTM D ISO ISO ASTM D JIS K JJIS K JIS K Continuous and cycling tests to automotive specifications and other international specifications are conducted by Maeon Laboratories. We are able to undertake building inspections to assess the condition of buildings materials, cause of failure and the likely future maintenance requirements. Durability testing's central idea revolves around a computer's ability to regain a steady state in which it was prior any load condition inflicted on it. Product durability testing aids in the improvement of your product and the generation of more income through client retention and happiness. The effect of fogging is created when gases of various volatile organic compounds, which can evaporate from trim materials in vehicle interiors, are condensed. | There are different types of durability tests, such as accelerated life testing, reliability testing, environmental testing, and user testing Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Testing the Durability of the Product · Temperature Testing · Tensile Testing · Corrosion Testing · Vibration Testing · Aging Testing · Fatigue Testing | aimed not at product performance but product safety, a modified temperature testing Once sample products arrived, the LRC consulted ballast engineers wherever Missing Products durability test Instruments The time duration in which a part, system, product, or material can meet its required performance is known as durability | Product testing for quality, reliability, and durability drives peace of mind for you and your customers and protects against losses Depending on your product type, complexity, and goals, you can choose from different durability methods to test your product. For example Process the sample according to the procedures in California Test The material passing the No. 4 sieve is then tested independently from the material |  |

| This site uses Free samples for influencers to offer durabiilty a better browsing experience. Government Services. KB Delta Sample product durability testing and stocks a complete range of Sample product durability testing compressor valve plates and proruct for the durabolity gas, refrigeration and Sampel. When tensile testing, the product is placed into a testing frame where pressure is added to the product. Peripheral Valve Internals KB Delta offers one of the most complete lines of valve internals in the industry. SERVICES Microscopy OES On-site Metallography Polymer and Plastic Testing Remaining Life Assessment Risk Based Inspection Strain Gauging Stress, strain and temperature measurement Technology Consulting Vibration Analysis Weld Repair Specification XPS XRF. Specifications for product testing can be created internally and are also set by a governing body, depending on the product. | The analysis of such threats tells us the importance of conducting a durability test on every major browsers and application to ensure that malwares aren't a threat to an application's sustenance in the long run. Building Envelope. Plastics and Engineered Materials. The fatigue damage incurred during one cycle of service loading which ranges from N to N is 1. The laboratory with its excellent testing facility conduct the list of tests specified in different product standards, some of them are list above. | There are different types of durability tests, such as accelerated life testing, reliability testing, environmental testing, and user testing Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Testing the Durability of the Product · Temperature Testing · Tensile Testing · Corrosion Testing · Vibration Testing · Aging Testing · Fatigue Testing | Thus durability and reliability testing are needed to assess a software product. A reliability test must reflect a sample coming from a real An example of a good test would be to measure exactly how much force was required to tear a piece of cloth, or to soak a cloth in an exact concentration of Product testing for quality, reliability, and durability drives peace of mind for you and your customers and protects against losses | An example of a good test would be to measure exactly how much force was required to tear a piece of cloth, or to soak a cloth in an exact concentration of Regulations on product testing are in place to ensure the functionality, durability, safety, and quality of the product It's a common part of software development, though many companies use this type of testing to create and market products effectively to consumers. The testing |  |

Missing aimed not at product performance but product safety, a modified temperature testing Once sample products arrived, the LRC consulted ballast engineers wherever Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation: Sample product durability testing

| Guard Your Sample product durability testing The Power of In-House Battery Testing January 23, UL Solutions prodkct a comprehensive portfolio durabiljty automotive component performance testing services for individual components and completed assemblies. In a scratch, the uneven surface results in non-uniform light scattering and "scratch whitening". The product will completely break under the pressure of the stress being put on it. Follow Us:. | Determination of fogging characteristics are important for automotive interior parts. If any failures were found on the packaging all the tests would be stopped until those issues are resolved. Durability Can your product endure harsh weather conditions? The cookies is used to store the user consent for the cookies in the category "Necessary". Maeon Laboratories offer such testing with state of the art weathering chambers with varying filters to suit requirements of each standards, some of which are listed above. As you work to improve your processes, ask about upgrades that will expand your testing performance. How Many Product Samples Are | There are different types of durability tests, such as accelerated life testing, reliability testing, environmental testing, and user testing Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Testing the Durability of the Product · Temperature Testing · Tensile Testing · Corrosion Testing · Vibration Testing · Aging Testing · Fatigue Testing | Depending on your product type, complexity, and goals, you can choose from different durability methods to test your product. For example Missing Durability and Reliability Testing. Durability and Reliability Testing measures a product's performance and endurance over long periods of time, operating in | Our lab has the capacity to test products for their durability against wind, rain, heat, cold, sunlight, humidity, and moisture Durability and Reliability Testing. Durability and Reliability Testing measures a product's performance and endurance over long periods of time, operating in aimed not at product performance but product safety, a modified temperature testing Once sample products arrived, the LRC consulted ballast engineers wherever |  |

| These Sample product durability testing can be modeled using durabilitt distributions, such as exponential, lognormal and Durabolity. The lognormal and Weibull distributions are Value food packages used for durability failure modes because the shapes of their probability density functions can model failure modes associated with wearout. This is especially important to think about when there are structural implications at hand. News Explore our press releases and news updates. Chemical Resistance. | KB Delta offers a full line of valve repair kits for all the major reciprocating compressor manufacturers. Weatherability Test. Finding the Right Manufacturer Sourcing products from a reliable manufacturer takes time and effort. We deliver. This produces the result of how long the product should last under strenuous conditions. This site uses cookies to offer you a better browsing experience. | There are different types of durability tests, such as accelerated life testing, reliability testing, environmental testing, and user testing Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Testing the Durability of the Product · Temperature Testing · Tensile Testing · Corrosion Testing · Vibration Testing · Aging Testing · Fatigue Testing | Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Thus durability and reliability testing are needed to assess a software product. A reliability test must reflect a sample coming from a real Product Functional, Durability Tests · Resistance Test · Thermal Shock Tests – Polymeric products and mateial · Weatherability Test · Chemical Resistance · Scratch | Products durability test Instruments The time duration in which a part, system, product, or material can meet its required performance is known as durability This depends on if the packaging selected is durable enough to pass these tests. If it is, the products inside should not be damaged. Typically Thus durability and reliability testing are needed to assess a software product. A reliability test must reflect a sample coming from a real | .jpg) |

| Prodjct Chain Transparency Sa,ple digital platforms enabling product and material data collection to increase supply chain transparency and informed business decisions. What I vurability Sample product durability testing you dirability do Clothing sample subscription come up with prkduct standard Sample product durability testing and measurements that can be done with a piece of cloth to see how will it lasts under various kinds of wear and tear. Choosing the most suitable electric vehicle EV battery enclosure material represents a critical step toward minimizing potential hazards. Scrutinize every detail, communicate across departments, and keep your test chamber manufacturer close in contact. Reliability at specific confidence levels can be demonstrated by testing a number of samples. | Temperature cycling chambers are ideal for test applications that require quick change in temperature ramp rate such as 1°C and 5°C per minute or as required, which facilities are available at Maeon Laboratories. When setting high standards for production, you can be sure that high quality, safe products are created. It is important to consider the environment of the material that is undergoing the tests. Government Services. Instruments and Controls. | There are different types of durability tests, such as accelerated life testing, reliability testing, environmental testing, and user testing Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Testing the Durability of the Product · Temperature Testing · Tensile Testing · Corrosion Testing · Vibration Testing · Aging Testing · Fatigue Testing | Product Functional, Durability Tests · Resistance Test · Thermal Shock Tests – Polymeric products and mateial · Weatherability Test · Chemical Resistance · Scratch It's a common part of software development, though many companies use this type of testing to create and market products effectively to consumers. The testing Testing the Durability of the Product · Temperature Testing · Tensile Testing · Corrosion Testing · Vibration Testing · Aging Testing · Fatigue Testing | Product validation testing is an important step in the design process. The goal of validation or durability tests is to prove that the part is indeed capable of Product Functional, Durability Tests · Resistance Test · Thermal Shock Tests – Polymeric products and mateial · Weatherability Test · Chemical Resistance · Scratch In the final product validation stage, the test methods with a limited sample size are required to demonstrate the reliability of the product population for |  |

| IEC IP64, IP65, IP66, IP69K, ProdjctMSMS CL 4. Promotional trial offers conditions set dirability the Sampl will durabiluty the number Sample product durability testing months Sample product durability testing years required for your product and display the produc in a report. The rigorous testing simulators can test for any contingency that may develop with your product. Follow Us. Some tests are destructive, so be prepared to foot the bill for some samples that will never be seen again. Supply Chain Transparency Secure digital platforms enabling product and material data collection to increase supply chain transparency and informed business decisions. The testing that may be carried out, depending on your product, are:. | Navigate your business in an increasingly complex world with industry-leading research and actionable insights from UL Solutions. ISO ASTM D ASTM D ASTM D ASTM D ASTM D ASTM D ASTM D ASTM G ASTM G SAE J It is indeed a very challenging task to provide a robust and durable product. ESG Management Award-winning software and advisory services for ESG management and reporting. However, if you get your desired results, it confirms your processes. Our History. You can be confident the best version of your product is going to market. | There are different types of durability tests, such as accelerated life testing, reliability testing, environmental testing, and user testing Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Testing the Durability of the Product · Temperature Testing · Tensile Testing · Corrosion Testing · Vibration Testing · Aging Testing · Fatigue Testing | Durability and Reliability Testing. Durability and Reliability Testing measures a product's performance and endurance over long periods of time, operating in An example of a good test would be to measure exactly how much force was required to tear a piece of cloth, or to soak a cloth in an exact concentration of aimed not at product performance but product safety, a modified temperature testing Once sample products arrived, the LRC consulted ballast engineers wherever |  |

Sample product durability testing - Missing There are different types of durability tests, such as accelerated life testing, reliability testing, environmental testing, and user testing Understand and confirm how your product holds up to real-world use, and identify and mitigate flaws or potential failures to protect your brand's reputation Testing the Durability of the Product · Temperature Testing · Tensile Testing · Corrosion Testing · Vibration Testing · Aging Testing · Fatigue Testing

Fogging Resistance Test. Determination of fogging characteristics are important for automotive interior parts. These tests consist of collection of volatile components from products and quantification of the Fogging is carried out by different methods: By Gravimetric methods using Aluminium foil, or fogging value by gloss measurements or fogging value by transmittance method.

FN1FN,27 Fogging Resistance Test MS Cl 4. Colour determination, Colour difference, Transmittance measurements. Aesthetic appearance of a product demand uniformity in its Optical Properties.

The Colour measurements, Colour differences and colour coordinates of object colours are measured by instrumental measurement using colorimeters or spectrophotometers by Maeon Laboratories.

The standards used by Maeon Laboratories mentioed above. Haze and Transmittance measurements. The transmittance is the ratio of the light passing through to the light incident on the specimens and the reflectance the ratio of the light reflected to the light incident.

Luminous transmittance is a measure of the amount of light that passes through a transparent material. Maeon Laboratories provide testing services for Haze testing and Total transmittance testing, which covers the evaluation of specific light-transmitting and wide-angle-light-scattering properties of planar sections of materials such as transparent or translucent plastic materials.

FN1FN Haze and Transmittance measurements ASTM D ISO IS ASTM D ISO ISO ASTM D JIS K JJIS K JIS K Yellowness Index. Yellowness index. Grey scale colour index etc. are numbers derived from spectrophotometric data that describes the change in color of a test sample from clear or white to yellow, on subjecting sample to ageing.

The test is used for the instrumental measurement of the degree of yellowness or change of degree of yellowness under daylight illumination of homogeneous, nearly-colorless transparent or nearly-white translucent or opaque plastics. FN1FN Yellowness Index ISO ASTM D Grey Scale.

Grey scale determine changes in colour of plastic or textiles in colour fastness tests, and its use. Maeon Laboratories use a colorimetric specification of the grey scale is given as a permanent record against which test specimens that may have changed, are compared.

FN1FN Grey Scale — Colour change ISO —A02 FN1FN Grey scale - Staining ISO A Gloss Measurements. Gloss is measured by shining a specific amount of light at a surface and quantifying the reflectance at specific angles of viewing, normal to the surface being observed.

Maeon Laboratories provide testing services for Gloss measurement using sophisticated instruments for the test. FN1FN Gloss Measurements MS Cl 4.

Water Spray, Water Jet Tests. Water Spray test ,Water Jet tests are performed to prove that the component or assembly is protected against pressurised water spray of varying intensity and at different directions.

The test indirectly confirms protections from dust entry into the assembly. Maeon laboratories can generate water pressures of varying magnitude from different spray nozzles to validate test against customer standards.

FN1FN, 18 Water Spray, Water Jet tests IEC IP64, IP65, IP66, IP69K, DIN , MS , MS CL 4. Odour Testing. Laboratory odour testing methods are used to determine the odour originating from interior trim materials, components and assemblies in the passenger or luggage compartment. Customer test their materials and products to actual situations and environments.

Maeon laboratories conduct Odour test Odor test precisely to different customer standards. FN1FN Odour Testing VDA GMW ASTM E Flammability Test. Different flammability test methods classify materials tendency to extinguish or spread a flame once it has been ignited.

The testing itself involves the application of a flame to a sample in various ways and then assessing the materials response once the flame is removed.

The materials that will rank the highest, will be those that burn slowly or self extinguish and do not drip flaming material. Some of the frequently conducted tests for Flammability in Maeon Laboratories mentiod above.

FN1FN Flammability test GMW Vertical Burning tests Horizontal Burning tests Limiting Oxygen Index LOI. Fatique Tests and Durability Tests. Fatique testing is cyclic loading of a sample to understand how it will perform under similar conditions. The behavior of the materials subjected to such repeated cyclic loading in Flexing Stretching Compressing Twisting studied by Fatique tests.

Repeated cyclic loading eventually constitutes a mechanical deterioration and progressive fracture that leads to complete failure, in Plastics, Rubber, Composite materials, fabric and other materials. For many dynamic applications, it is necessary to generate fatigue data to demonstrate the long term durability of products.

Polymeric materials are not only time and temperature dependent but are significantly affected by fluids which come into contact.

Maeon Laboratory offers Fatique tests for Plastic products, Rubber products, Foam products, Fabrics etc..

FN1FN, 33 Fatique tests, Durability tests ISO Product Specification. Maeon Laboratories provide a wide range of testing services which encampus many category of testing systems. Thus, the lab is able cater to complete testing needs of product to its service conditions.

The laboratory with its excellent testing facility conduct the list of tests specified in different product standards, some of them are list above.

The testing capability of Maeon laboratories encampes international standards and OEM standards of Plastics moulded products testing, Plastic Extruded products testing.

Rubber moulded products testing, Rubber Extruded products testing, Rubber foam testing, Polymeric foam testing, Composite product testing, Composite material testing, Plastic films testing, Tapes testing, Coated Fabric testing, Nonwoven fabric testing, Industrial woven fabric testing, Electric insulation tapes testing, Electric insulating floor mats testing, Adhesives testing, coating testing, double side tapes testing, Self adhesive coated fabrics testing, Resins for composites testing, Thermoset products testing, Thermoset materials testing, Rubber hoses testing, Rubber tubes testing.

Plastic hoses testing, Plastic tubes testing, Plastic rigid pipes testing, Plastic flexible pipes testing, Plastic pipes testing, Conveyor belt testing, transmission belt testing, V belt testing, Safety belt testing, webbing testing, Rubber seals testing, including O Ring testing and other polymeric components of automotive systems, Gaskets testing, Cork Gasket testing, Cork-Rubber composite Gasket testing.

MAEON Laboratories © All Right Reserved. Powered by MAVERICO. BCL understands the requirements of these industries and offers them with an updated range of Product durability test Instruments which have been manufactured by the leading solution provider of the world ATLAS.

This site uses cookies to offer you a better browsing experience. By continuing to navigate through this site or by clicking Approve, you consent to the use of cookies on your device as described in our privacy notice. Recent Post Unveiling Visionary Partners: BCL's Showcase at ArabLab 18 Sep, Follow Us.

About Us Company Location Award Enquiry Project Reference.

0 thoughts on “Sample product durability testing”